A Manufacturing Specialist plays a key role in the production process, ensuring that products are made efficiently and meet quality standards. They are responsible for overseeing the manufacturing process, troubleshooting issues, and maintaining equipment.

Skills required for a Manufacturing Specialist include technical knowledge of manufacturing equipment, attention to detail, and the ability to work well under pressure. Additionally, strong problem-solving skills and effective communication are crucial for success in this role.

Candidates can write these abilities in their resumes, but you can’t verify them without on-the-job Manufacturing Specialist skill tests.

In this post, we will explore 8 essential Manufacturing Specialist skills, 10 secondary skills and how to assess them so you can make informed hiring decisions.

Table of contents

8 fundamental Manufacturing Specialist skills and traits

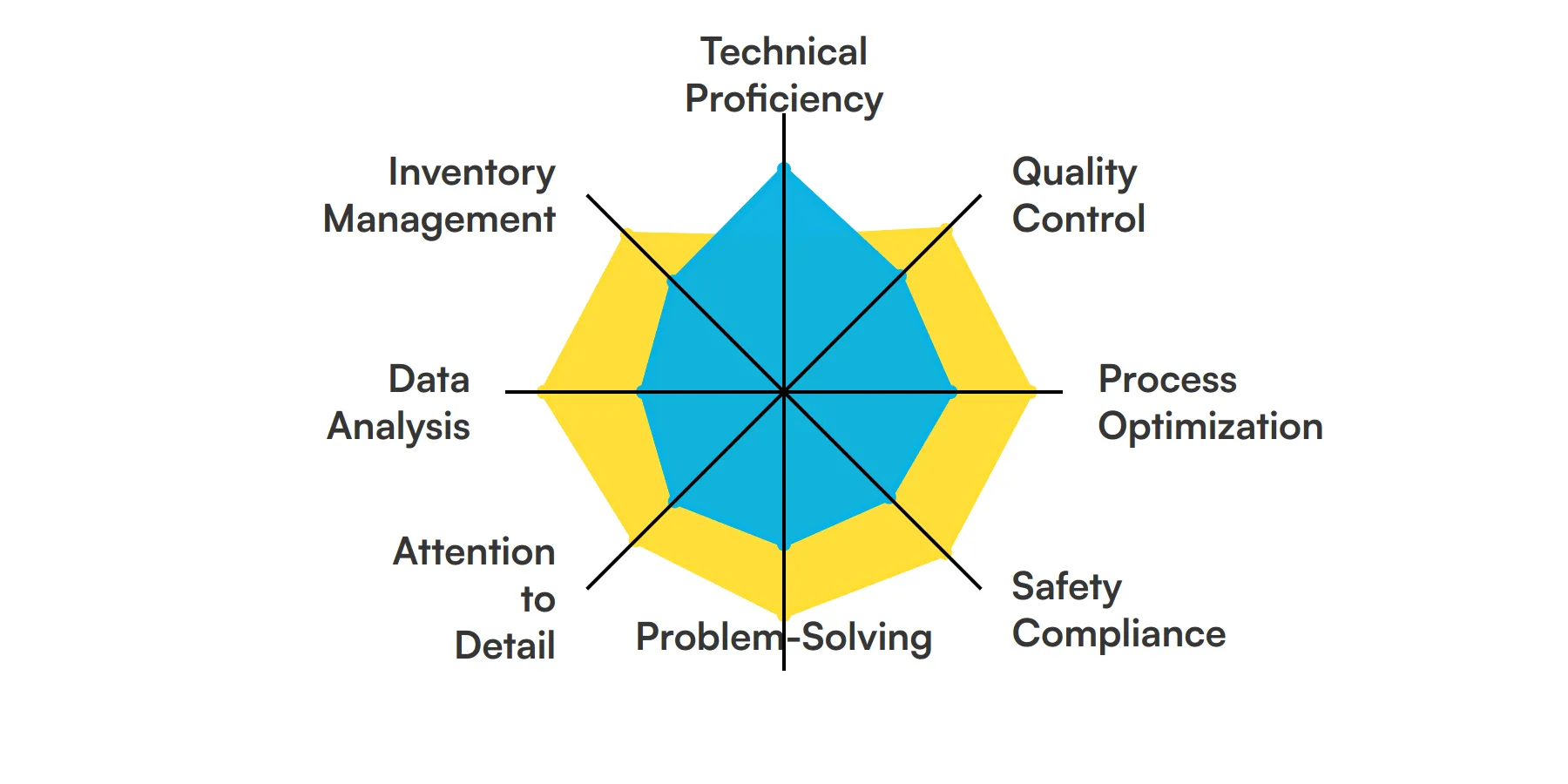

The best skills for Manufacturing Specialists include Technical Proficiency, Quality Control, Process Optimization, Safety Compliance, Problem-Solving, Attention to Detail, Data Analysis and Inventory Management.

Let’s dive into the details by examining the 8 essential skills of a Manufacturing Specialist.

Technical Proficiency

A manufacturing specialist must have a strong grasp of technical skills related to machinery and equipment. This includes understanding how to operate, troubleshoot, and maintain various types of manufacturing technology.

For more insights, check out our guide to writing a Manufacturing Specialist Job Description.

Quality Control

Ensuring the products meet specific standards is a key responsibility. This involves conducting inspections, identifying defects, and implementing corrective actions to maintain high-quality output.

Process Optimization

The ability to analyze and improve manufacturing processes is crucial. This skill helps in reducing waste, increasing efficiency, and enhancing overall productivity.

Safety Compliance

A manufacturing specialist must be well-versed in safety regulations and protocols. This ensures a safe working environment and minimizes the risk of accidents and injuries.

Check out our guide for a comprehensive list of interview questions.

Problem-Solving

Quickly identifying and resolving issues that arise during the manufacturing process is essential. This skill helps in maintaining smooth operations and minimizing downtime.

Attention to Detail

Precision is key in manufacturing. A keen eye for detail ensures that every component and product meets the required specifications and standards.

Data Analysis

Interpreting data from various sources to make informed decisions is important. This includes analyzing production metrics, quality reports, and other relevant data to optimize performance.

For more insights, check out our guide to writing a Data Analyst Job Description.

Inventory Management

Managing raw materials and finished products efficiently is crucial. This involves tracking inventory levels, ordering supplies, and ensuring that production schedules are met.

10 secondary Manufacturing Specialist skills and traits

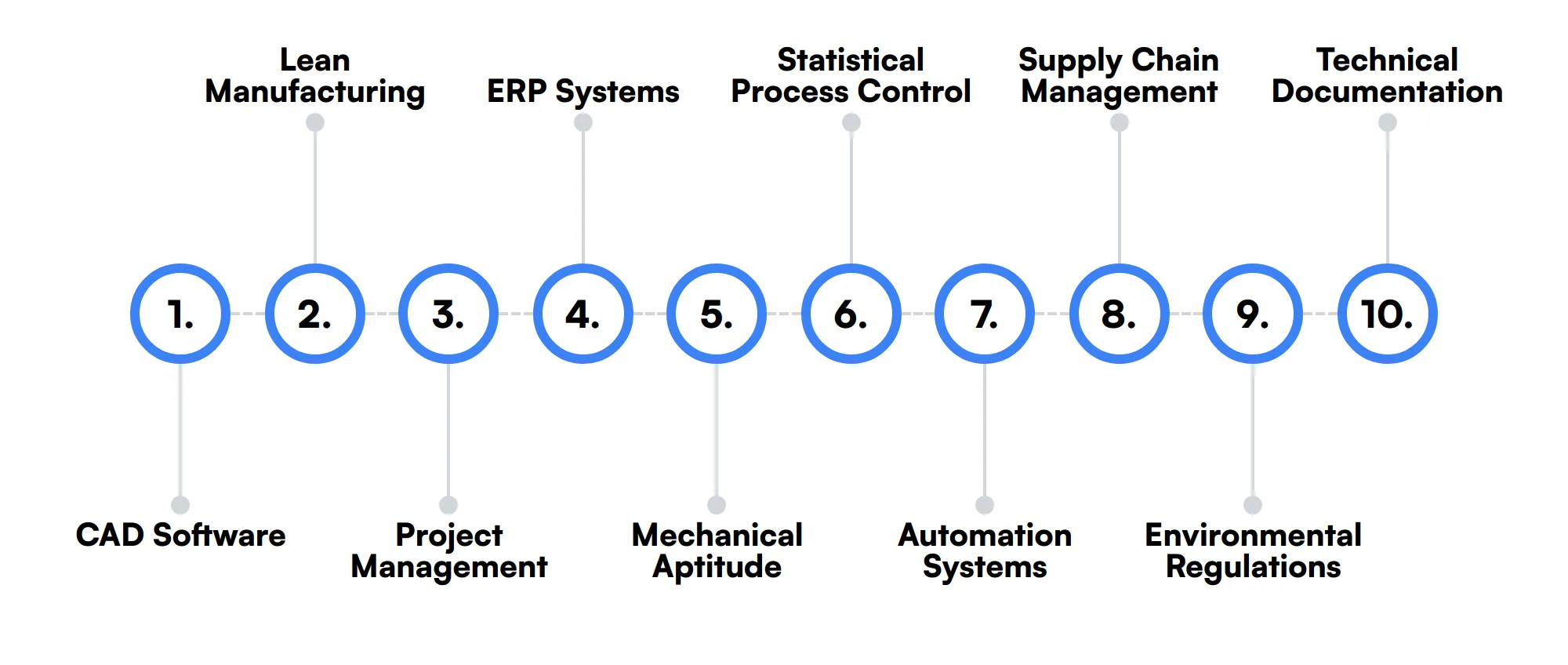

The best skills for Manufacturing Specialists include CAD Software, Lean Manufacturing, Project Management, ERP Systems, Mechanical Aptitude, Statistical Process Control, Automation Systems, Supply Chain Management, Environmental Regulations and Technical Documentation.

Let’s dive into the details by examining the 10 secondary skills of a Manufacturing Specialist.

CAD Software

Familiarity with Computer-Aided Design (CAD) software can be beneficial for creating and modifying product designs.

Lean Manufacturing

Understanding lean manufacturing principles helps in minimizing waste and maximizing productivity.

Project Management

Managing projects effectively ensures that manufacturing goals are met on time and within budget.

ERP Systems

Experience with Enterprise Resource Planning (ERP) systems aids in integrating various business processes and improving overall efficiency.

Mechanical Aptitude

A good understanding of mechanical systems and components is useful for troubleshooting and maintaining equipment.

Statistical Process Control

Using statistical methods to monitor and control manufacturing processes helps in maintaining consistent quality.

Automation Systems

Knowledge of automation systems and robotics can enhance production efficiency and reduce manual labor.

Supply Chain Management

Understanding the supply chain process helps in ensuring timely delivery of materials and products.

Environmental Regulations

Awareness of environmental regulations ensures that manufacturing processes comply with legal standards and minimize environmental impact.

Technical Documentation

The ability to create and interpret technical documents, such as blueprints and manuals, is important for accurate production and maintenance.

How to assess Manufacturing Specialist skills and traits

Assessing the skills and traits of a Manufacturing Specialist can be a challenging task, given the diverse range of competencies required for the role. From technical proficiency and quality control to process optimization and safety compliance, each skill plays a significant role in ensuring efficient manufacturing operations. It's important to have a structured approach to evaluate these skills effectively.

Traditional resumes and interviews may not provide a complete picture of a candidate's abilities. This is where skills-based assessments come into play. By using targeted assessments, you can gain a deeper understanding of a candidate's problem-solving abilities, attention to detail, and data analysis skills. Adaface assessments can help you achieve a 2x improved quality of hires and an 85% reduction in screening time, making the hiring process more efficient and accurate.

Let’s look at how to assess Manufacturing Specialist skills with these 6 talent assessments.

Technical Aptitude Test

Our Technical Aptitude Test evaluates a candidate's understanding of basic computer concepts, programming fundamentals, and more complex topics like database management and software engineering.

The test assesses their ability to apply critical thinking and analytical skills to solve technical problems, covering areas such as data structures, networking, and system administration.

Candidates successful in this test demonstrate strong problem-solving skills and a solid grasp of technical concepts necessary for roles requiring technical aptitude.

QA Engineer Test

Our QA Engineer Test measures a candidate's proficiency in Quality Assurance, including testing fundamentals and test design techniques.

This test evaluates knowledge in test automation frameworks, regression testing, and bug tracking, with specific focus on Selenium and Linux fundamentals.

High-scoring candidates will show a thorough understanding of the software life cycle and the ability to design and execute comprehensive test plans.

Loadrunner Online Test

The Loadrunner Online Test assesses a candidate's ability to use Loadrunner for performance testing of web applications.

Candidates are tested on Loadrunner basics, scripting, load testing concepts, and performance analysis, including parameterization and correlation.

Successful candidates will demonstrate proficiency in managing test scenarios and analyzing results to ensure optimal performance and scalability.

Problem Solving Test

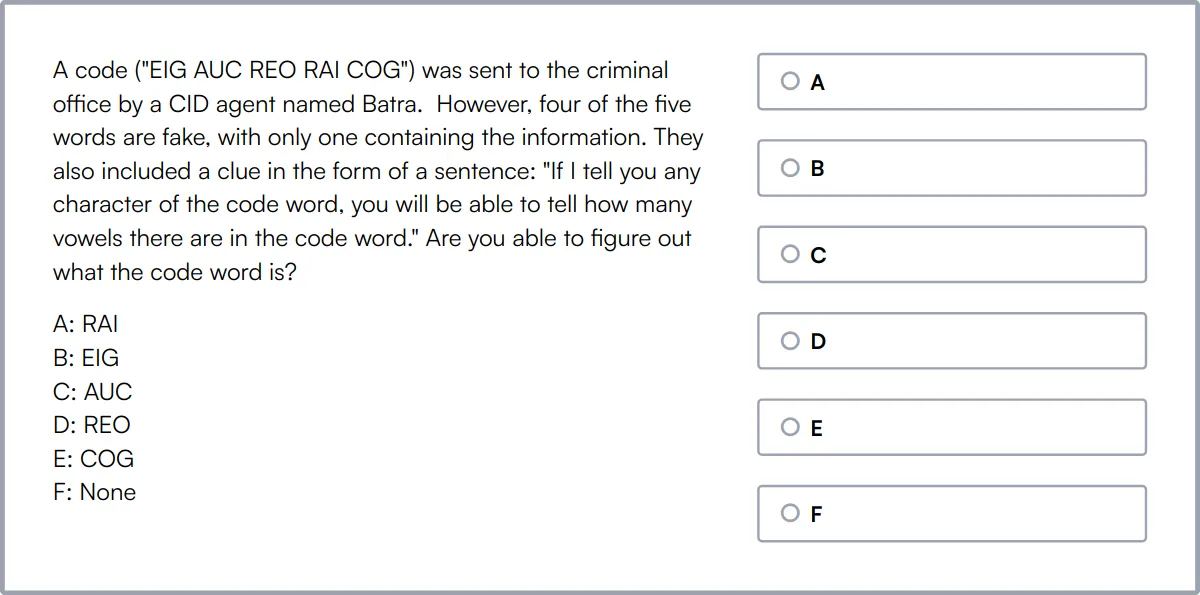

Our Problem Solving Test evaluates a candidate's ability to analyze data and respond to complex problems using logical and critical thinking.

The test covers abstract reasoning, spatial reasoning, and data interpretation, challenging candidates to apply deductive and inductive reasoning to real-world scenarios.

Candidates excelling in this test will display strong problem-solving capabilities and the ability to adapt and learn quickly in challenging environments.

Attention To Detail Test

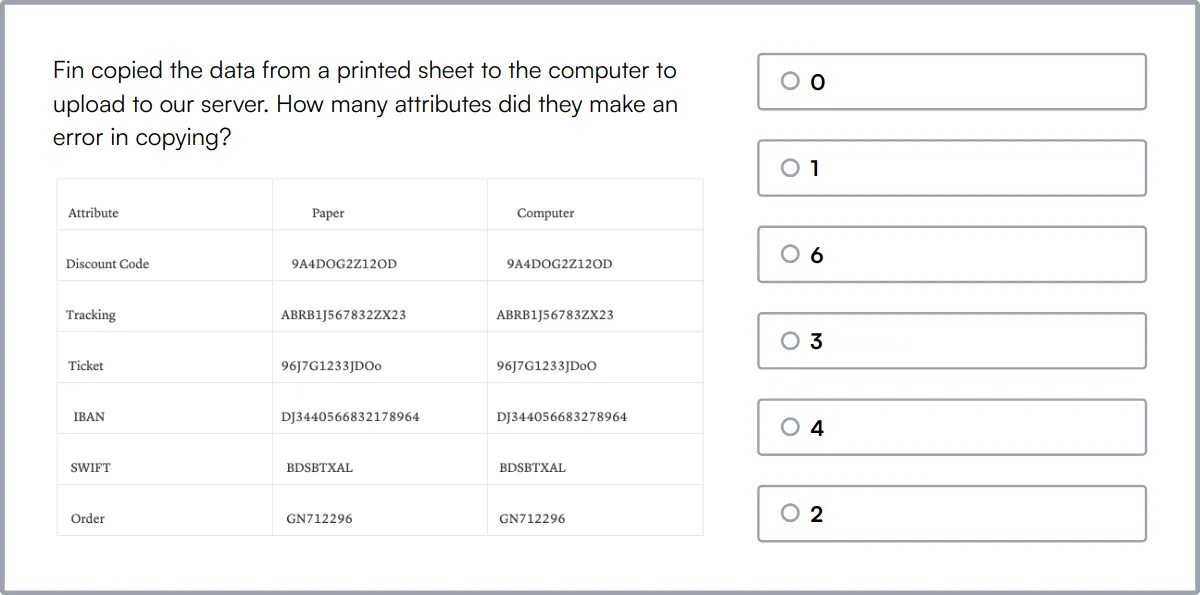

The Attention to Detail Test evaluates how well a candidate can process information with precision and thoroughness.

It assesses skills in following instructions, verifying data, and identifying inconsistencies, crucial for roles requiring meticulous attention to detail.

Candidates who score well on this test are likely to perform tasks with high accuracy and maintain quality in detail-oriented work.

Data Analysis Test

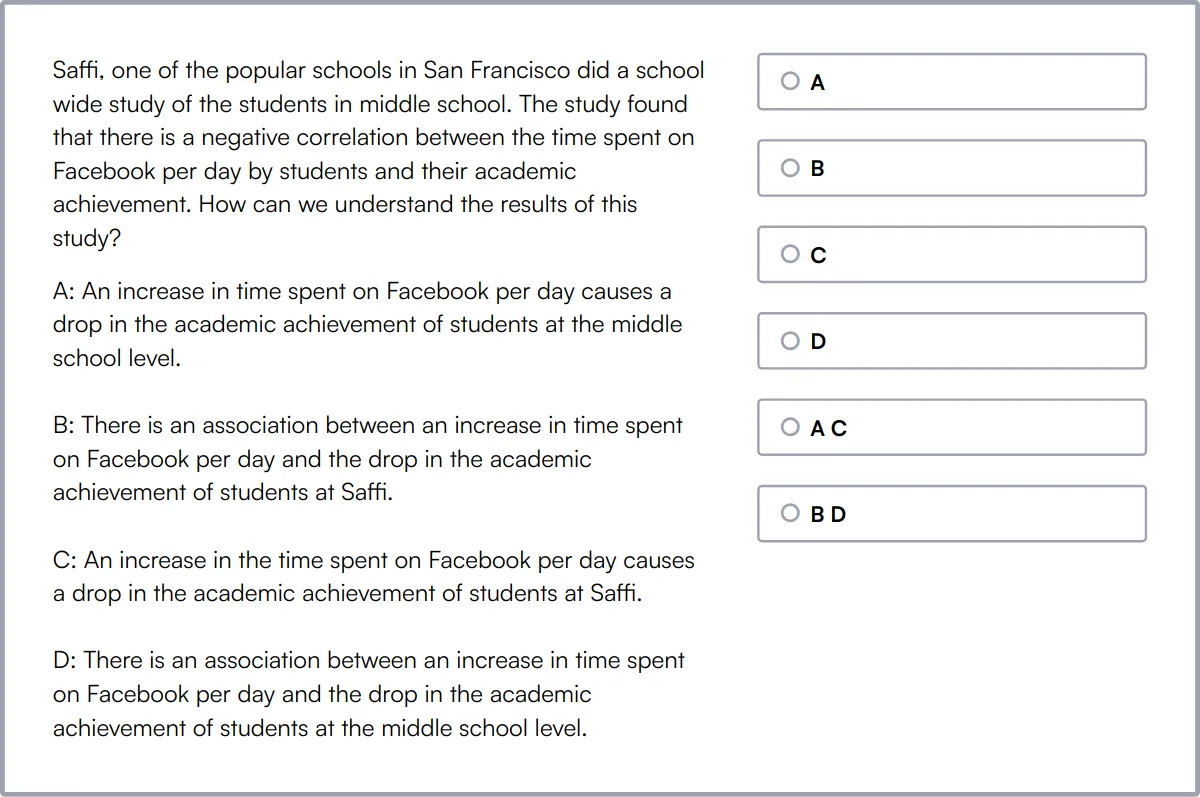

Our Data Analysis Test assesses a candidate's ability to handle and interpret data, crucial for roles in business and data analysis.

The test challenges candidates with questions on data modeling, SQL queries, and data interpretation, using scenario-based MCQs to evaluate their analytical skills.

High performers in this test are adept at extracting insights from data and can effectively use tools like Excel to support business decisions.

Summary: The 8 key Manufacturing Specialist skills and how to test for them

| Manufacturing Specialist skill | How to assess them |

|---|---|

| 1. Technical Proficiency | Evaluate hands-on experience with manufacturing tools and machinery. |

| 2. Quality Control | Check ability to maintain product standards and perform inspections. |

| 3. Process Optimization | Assess skills in improving manufacturing processes for better efficiency. |

| 4. Safety Compliance | Verify knowledge of safety protocols and adherence to regulations. |

| 5. Problem-Solving | Determine capability to identify and resolve manufacturing issues. |

| 6. Attention to Detail | Gauge precision in tasks and accuracy in documentation. |

| 7. Data Analysis | Evaluate proficiency in interpreting and utilizing manufacturing data. |

| 8. Inventory Management | Check skills in tracking and managing inventory levels. |

Software Support Specialist Test

Manufacturing Specialist skills FAQs

What technical skills should a Manufacturing Specialist have?

A Manufacturing Specialist should be proficient in CAD software, understand ERP systems, and have a good grasp of automation systems. Knowledge of statistical process control and mechanical aptitude are also important.

How can you assess problem-solving skills in Manufacturing Specialists?

Assess problem-solving skills by presenting candidates with real-world scenarios related to manufacturing challenges. Evaluate their approach to identifying, analyzing, and solving these problems.

What are key safety compliance skills for a Manufacturing Specialist?

Key skills include knowledge of OSHA regulations, ability to conduct risk assessments, and understanding of workplace safety protocols. Regular training and certifications in safety compliance are also beneficial.

Why is attention to detail important in manufacturing?

Attention to detail ensures high-quality production with minimal errors. It's critical for maintaining standards in quality control and process optimization, directly impacting product reliability and customer satisfaction.

How important is data analysis for a Manufacturing Specialist?

Data analysis is crucial for making informed decisions in manufacturing. It helps in identifying trends, improving processes, and enhancing product quality through statistical analysis and interpretation of production data.

What inventory management skills are necessary for a Manufacturing Specialist?

Effective inventory management requires skills in tracking stock levels, forecasting supply needs, and coordinating with supply chain operations to ensure adequate material availability without overstocking.

How does knowledge of environmental regulations impact a Manufacturing Specialist?

Understanding environmental regulations is key to ensuring manufacturing processes comply with legal standards. This knowledge helps prevent legal issues and promotes sustainable manufacturing practices.

What project management skills are essential for a Manufacturing Specialist?

Project management skills include planning, scheduling, resource allocation, and timeline management. These skills help ensure that manufacturing projects are completed on time and within budget.

Assess and hire the best Manufacturing Specialists with Adaface

Assessing and finding the best Manufacturing Specialist is quick and easy when you use talent assessments. You can check out our product tour, sign up for our free plan to see talent assessments in action or view the demo here:

40 min skill tests.

No trick questions.

Accurate shortlisting.

We make it easy for you to find the best candidates in your pipeline with a 40 min skills test.

Try for freeRelated posts

Free resources