Hiring the right candidate for Microsoft Dynamics 365 SCM Manufacturing roles can be challenging, especially when you need someone who understands both the technical and process aspects of the job. Having a structured list of interview questions is essential to accurately assess a candidate’s proficiency and ensure they are the right fit for your company. manufacturing specialist.

In this blog post, we will provide you with a comprehensive list of interview questions that focus on various aspects of Microsoft Dynamics 365 SCM Manufacturing. These questions are categorized to evaluate different levels of expertise, from junior specialists to top-tier candidates, and cover areas like processes, tasks, and system configurations.

Using these questions will help you conduct more effective interviews and make well-informed hiring decisions. Additionally, consider leveraging our Microsoft Dynamics 365 SCM Manufacturing Functional Consultant Test to pre-screen candidates before the interview stage.

Table of contents

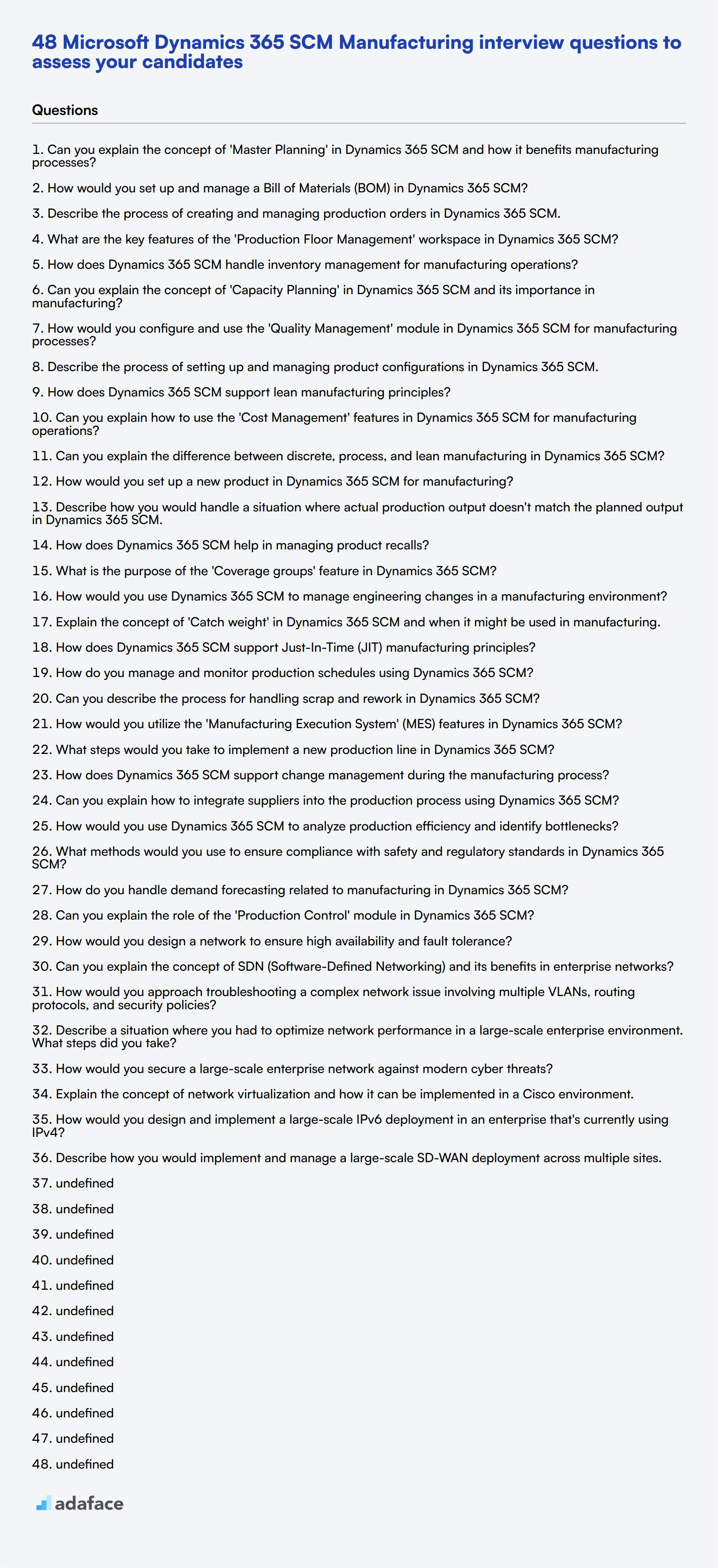

10 common Microsoft Dynamics 365 SCM Manufacturing interview questions to ask your candidates

To assess candidates' proficiency in Microsoft Dynamics 365 SCM Manufacturing, use these interview questions to gauge their understanding of key features and processes. These questions are designed to help you identify skilled candidates who can effectively leverage the platform for your organization's manufacturing operations.

- Can you explain the concept of 'Master Planning' in Dynamics 365 SCM and how it benefits manufacturing processes?

- How would you set up and manage a Bill of Materials (BOM) in Dynamics 365 SCM?

- Describe the process of creating and managing production orders in Dynamics 365 SCM.

- What are the key features of the 'Production Floor Management' workspace in Dynamics 365 SCM?

- How does Dynamics 365 SCM handle inventory management for manufacturing operations?

- Can you explain the concept of 'Capacity Planning' in Dynamics 365 SCM and its importance in manufacturing?

- How would you configure and use the 'Quality Management' module in Dynamics 365 SCM for manufacturing processes?

- Describe the process of setting up and managing product configurations in Dynamics 365 SCM.

- How does Dynamics 365 SCM support lean manufacturing principles?

- Can you explain how to use the 'Cost Management' features in Dynamics 365 SCM for manufacturing operations?

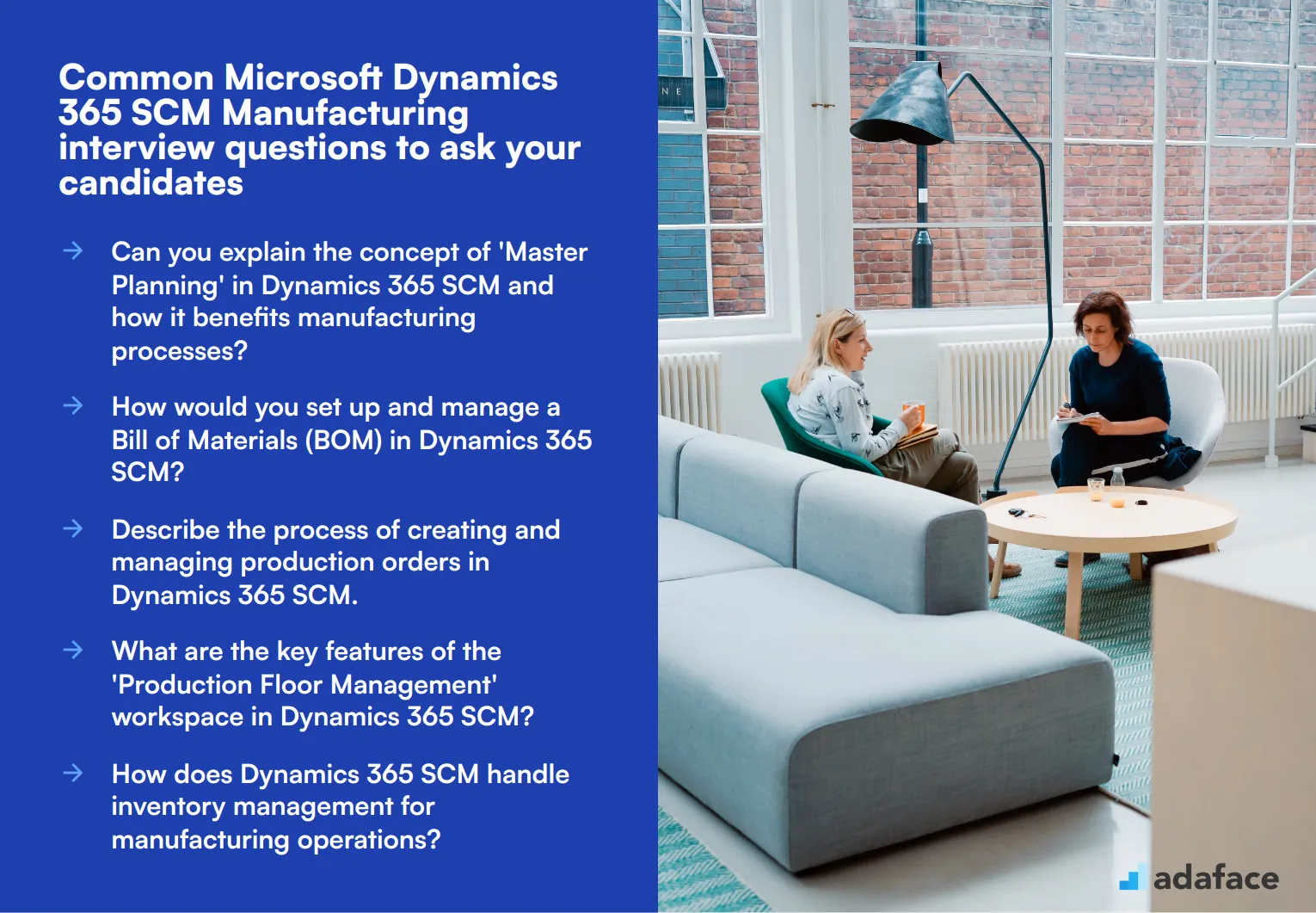

8 Microsoft Dynamics 365 SCM Manufacturing interview questions and answers to evaluate junior specialists

When evaluating junior specialists for Microsoft Dynamics 365 SCM Manufacturing roles, it's crucial to ask questions that assess their foundational knowledge and problem-solving skills. This curated list of questions will help you gauge candidates' understanding of key concepts and their ability to apply them in real-world scenarios. Remember, the goal is to find someone who can grow into the role, so focus on potential rather than expecting expert-level responses.

1. Can you explain the difference between discrete, process, and lean manufacturing in Dynamics 365 SCM?

A strong candidate should be able to differentiate between these three manufacturing types in Dynamics 365 SCM:

- Discrete manufacturing: Produces distinct items like cars or furniture. It uses bills of materials (BOMs) and routes.

- Process manufacturing: Creates products in bulk quantities, like chemicals or food. It uses formulas and co-products/by-products.

- Lean manufacturing: Focuses on minimizing waste and improving efficiency. It uses kanban and pull-based systems.

Look for candidates who can provide examples of each type and explain how Dynamics 365 SCM supports these different manufacturing processes. Follow up by asking which type they have the most experience with and why.

2. How would you set up a new product in Dynamics 365 SCM for manufacturing?

A junior specialist should be able to outline the basic steps for setting up a new product:

- Navigate to Product information management

- Create a new released product

- Fill in required fields like product number, name, and product type

- Set up product dimensions if applicable

- Define inventory settings

- Create or assign a BOM and route

- Set up costing information

- Release the product to the relevant legal entities

Look for candidates who mention the importance of production worker collaboration in this process. Strong answers will also touch on the need to consider product variants and how they affect the setup process.

3. Describe how you would handle a situation where actual production output doesn't match the planned output in Dynamics 365 SCM.

A good answer should include the following steps:

- Review the production order details in Dynamics 365 SCM

- Check for any reported errors or issues on the shop floor

- Verify if all materials were available and consumed correctly

- Examine resource capacity and utilization

- Adjust the production order quantity if necessary

- Update inventory levels and cost calculations

- Analyze the discrepancy for future process improvements

Look for candidates who emphasize the importance of root cause analysis and continuous improvement. They should also mention the need to communicate with relevant stakeholders, such as production managers and inventory controllers, to ensure everyone is aware of the discrepancy and its impact.

4. How does Dynamics 365 SCM help in managing product recalls?

A junior specialist should be able to explain that Dynamics 365 SCM provides several features to manage product recalls effectively:

- Lot traceability: Allows tracking of materials from supplier to customer

- Quarantine management: Enables isolation of affected inventory

- Quality orders: Facilitates testing and inspection of recalled products

- Return order processing: Manages the return of recalled items

- Reporting tools: Helps in analyzing the scope and impact of the recall

Look for candidates who understand the importance of swift action and clear communication during a recall. They should also mention how Dynamics 365 SCM can help in preventive measures by identifying patterns in quality issues before they escalate to a full recall.

5. What is the purpose of the 'Coverage groups' feature in Dynamics 365 SCM?

Coverage groups in Dynamics 365 SCM are used to define and manage inventory replenishment strategies. A good answer should explain that coverage groups:

- Help determine when and how much inventory to order

- Allow for different replenishment methods (e.g., min/max, period coverage, requirement)

- Can be assigned to items or item groups

- Influence master planning calculations

- Help balance inventory levels with demand

Look for candidates who can provide examples of when different coverage settings might be used. For instance, they might mention using period coverage for seasonal items or min/max for stable demand items. A strong answer will also touch on how coverage groups contribute to efficient inventory management and cost control.

6. How would you use Dynamics 365 SCM to manage engineering changes in a manufacturing environment?

A junior specialist should be able to outline the basic process of managing engineering changes:

- Create an engineering change request

- Evaluate the impact of the change

- Create an engineering change order

- Define the affected products and components

- Specify the effective date for the change

- Route the change order for approval

- Implement the approved changes in the system

- Update related documents (BOMs, routes, etc.)

Look for candidates who understand the importance of version control and the impact of changes on existing inventory and production orders. They should also mention the need for clear communication with all affected departments, including design, production, and procurement. A strong answer might also touch on how Dynamics 365 SCM helps maintain a history of changes for auditing and traceability purposes.

7. Explain the concept of 'Catch weight' in Dynamics 365 SCM and when it might be used in manufacturing.

Catch weight is a feature in Dynamics 365 SCM used for products that vary in weight or size but are sold in standard units. A good answer should explain:

- Catch weight allows tracking of both the nominal quantity (e.g., cases) and the actual quantity (e.g., weight)

- It's commonly used in food manufacturing, where products like meat or cheese can vary in weight

- The system can calculate prices based on the actual weight rather than just the number of units

- It helps in accurate inventory valuation and costing

Look for candidates who can provide examples of how catch weight might be used in a manufacturing process. They should understand that this feature is crucial for industries dealing with natural products or where precise measurements are important for quality control and pricing. A strong answer might also mention how catch weight affects warehouse management and shipping processes.

8. How does Dynamics 365 SCM support Just-In-Time (JIT) manufacturing principles?

A junior specialist should be able to explain that Dynamics 365 SCM supports JIT manufacturing through several features:

- Kanban management: Allows for pull-based production and material flow

- Lean order planning: Helps in creating production schedules aligned with demand

- Vendor-managed inventory: Facilitates close coordination with suppliers

- Real-time data and analytics: Enables quick response to changes in demand or supply

- Integration with IoT devices: Allows for real-time tracking of production and inventory

Look for candidates who understand that JIT is not just about inventory reduction but also about improving overall efficiency and quality. They should be able to explain how Dynamics 365 SCM's features work together to create a more responsive and lean manufacturing environment. A strong answer might also touch on the challenges of implementing JIT and how the system can help address them.

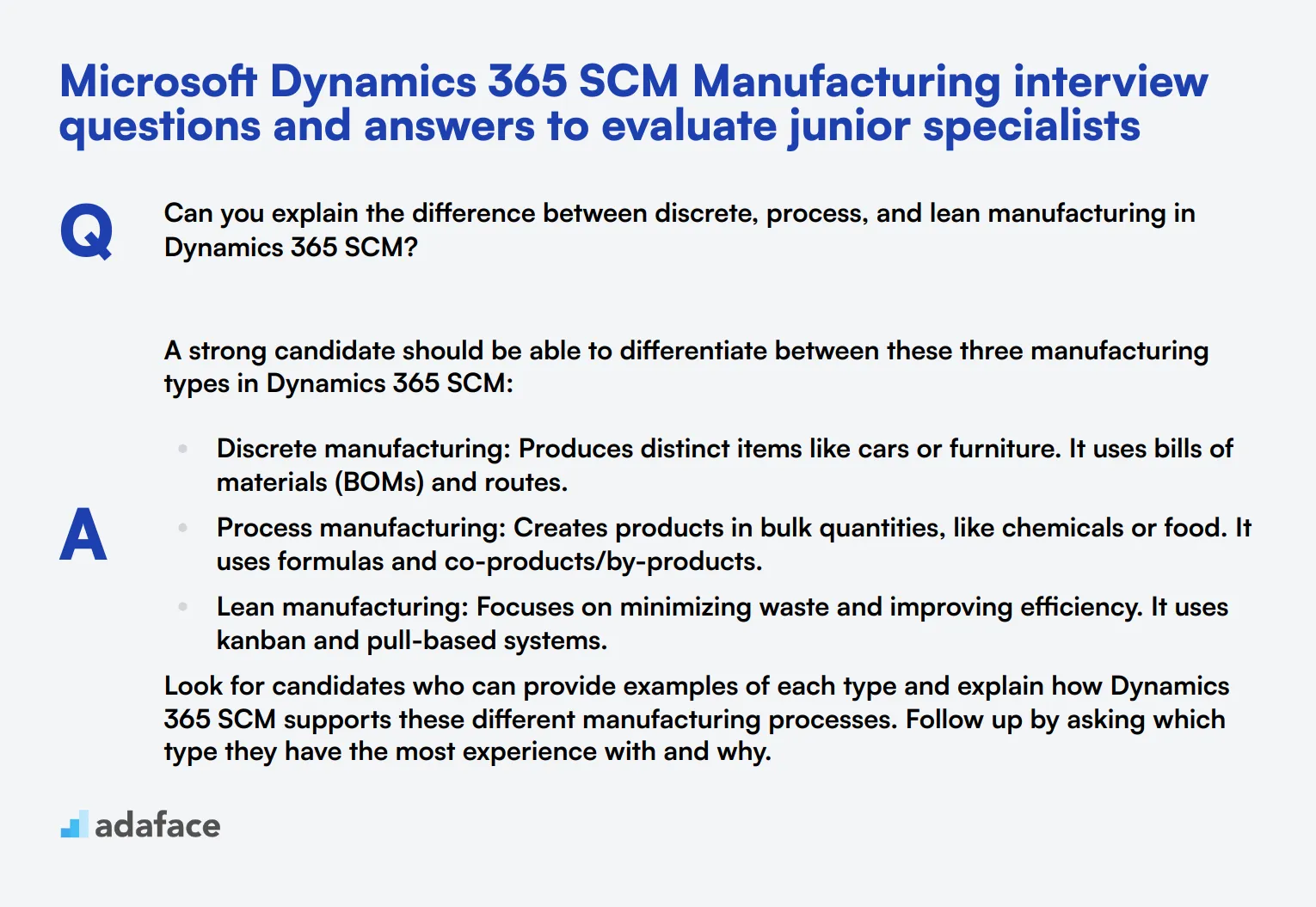

10 Microsoft Dynamics 365 SCM Manufacturing interview questions about processes and tasks

To ensure candidates possess the necessary skills and knowledge for manufacturing roles, utilize this set of interview questions about processes and tasks in Microsoft Dynamics 365 SCM. These questions will help you gauge their practical understanding and readiness for real-world challenges in manufacturing. For more insights into roles, check out this manufacturing engineer job description.

- How do you manage and monitor production schedules using Dynamics 365 SCM?

- Can you describe the process for handling scrap and rework in Dynamics 365 SCM?

- How would you utilize the 'Manufacturing Execution System' (MES) features in Dynamics 365 SCM?

- What steps would you take to implement a new production line in Dynamics 365 SCM?

- How does Dynamics 365 SCM support change management during the manufacturing process?

- Can you explain how to integrate suppliers into the production process using Dynamics 365 SCM?

- How would you use Dynamics 365 SCM to analyze production efficiency and identify bottlenecks?

- What methods would you use to ensure compliance with safety and regulatory standards in Dynamics 365 SCM?

- How do you handle demand forecasting related to manufacturing in Dynamics 365 SCM?

- Can you explain the role of the 'Production Control' module in Dynamics 365 SCM?

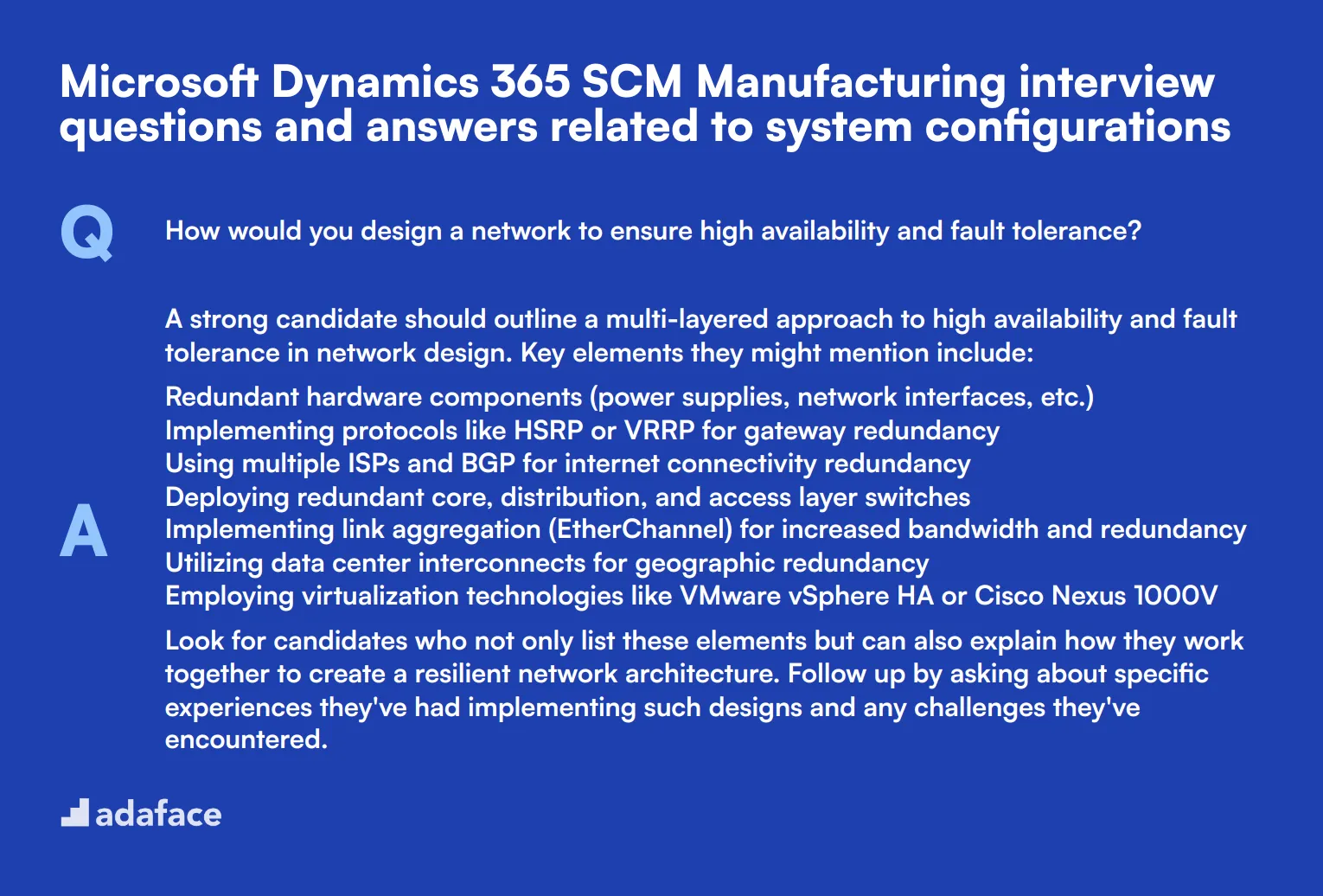

8 Microsoft Dynamics 365 SCM Manufacturing interview questions and answers related to system configurations

Ready to put your senior network engineer candidates through their paces? These 8 advanced Cisco Networking interview questions will help you evaluate their deep technical knowledge and problem-solving skills. Use these questions to assess candidates' ability to handle complex networking scenarios and implement solutions in enterprise environments.

1. How would you design a network to ensure high availability and fault tolerance?

A strong candidate should outline a multi-layered approach to high availability and fault tolerance in network design. Key elements they might mention include:

- Redundant hardware components (power supplies, network interfaces, etc.)

- Implementing protocols like HSRP or VRRP for gateway redundancy

- Using multiple ISPs and BGP for internet connectivity redundancy

- Deploying redundant core, distribution, and access layer switches

- Implementing link aggregation (EtherChannel) for increased bandwidth and redundancy

- Utilizing data center interconnects for geographic redundancy

- Employing virtualization technologies like VMware vSphere HA or Cisco Nexus 1000V

Look for candidates who not only list these elements but can also explain how they work together to create a resilient network architecture. Follow up by asking about specific experiences they've had implementing such designs and any challenges they've encountered.

2. Can you explain the concept of SDN (Software-Defined Networking) and its benefits in enterprise networks?

Software-Defined Networking (SDN) is an approach to network management that enables dynamic, programmatically efficient network configuration to improve network performance and monitoring. It separates the network's control plane (decision-making) from the data plane (packet forwarding).

Benefits of SDN in enterprise networks include:

- Centralized network provisioning and management

- Increased network flexibility and agility

- Improved network security through granular control

- Enhanced ability to implement network-wide policies

- Reduced operational costs through automation

- Better support for cloud services and virtualization

- Easier implementation of network changes and updates

A strong candidate should be able to explain these concepts clearly and provide examples of SDN implementations they've worked with, such as Cisco ACI or VMware NSX. Look for understanding of how SDN can address specific enterprise networking challenges and its potential impact on network management roles.

3. How would you approach troubleshooting a complex network issue involving multiple VLANs, routing protocols, and security policies?

An experienced network engineer should describe a systematic approach to troubleshooting complex network issues. A strong answer might include the following steps:

- Gather information about the specific problem and affected areas

- Review network topology and recent changes

- Use monitoring tools to identify potential bottlenecks or anomalies

- Verify VLAN configurations and trunking

- Check routing tables and protocol operations

- Examine security policies and firewall rules

- Use packet capture and analysis tools if necessary

- Isolate the problem by testing each network segment

- Consult documentation and vendor resources if needed

- Implement and test a solution

- Document the issue and resolution

Look for candidates who emphasize a methodical approach, demonstrate knowledge of various troubleshooting tools, and show the ability to break down complex problems into manageable components. Ask for specific examples of challenging issues they've resolved to gauge their real-world experience.

4. Describe a situation where you had to optimize network performance in a large-scale enterprise environment. What steps did you take?

This question assesses the candidate's practical experience in improving network efficiency. A strong answer might include:

- Conducting a thorough network assessment using tools like Wireshark or NetFlow

- Identifying bottlenecks and performance issues

- Implementing QoS policies to prioritize critical traffic

- Optimizing routing protocols and configuring route summarization

- Upgrading hardware where necessary

- Implementing caching solutions for frequently accessed data

- Fine-tuning TCP/IP stack parameters

- Segmenting the network to reduce broadcast domains

- Implementing WAN acceleration techniques

- Monitoring and fine-tuning the optimizations

Look for candidates who can provide specific examples of optimization techniques they've used and the results they achieved. Pay attention to their approach to measuring performance improvements and their ability to balance technical solutions with business needs.

5. How would you secure a large-scale enterprise network against modern cyber threats?

A comprehensive answer to this question should demonstrate the candidate's understanding of multi-layered security approaches. Key elements might include:

- Implementing robust firewalls and intrusion prevention systems (IPS)

- Utilizing network segmentation and micro-segmentation

- Deploying strong authentication mechanisms (e.g., 802.1X, multi-factor authentication)

- Implementing encrypted communications (e.g., VPNs, SSL/TLS)

- Regular security audits and vulnerability assessments

- Employing network access control (NAC) solutions

- Implementing SIEM (Security Information and Event Management) systems

- Ensuring proper patch management and system updates

- User education and security awareness training

- Implementing data loss prevention (DLP) solutions

Look for candidates who not only list security measures but also understand how they work together to create a comprehensive security strategy. Ask about their experience in implementing these measures and how they stay updated on emerging threats and security technologies.

6. Explain the concept of network virtualization and how it can be implemented in a Cisco environment.

Network virtualization is the process of combining hardware and software network resources into a single, software-based administrative entity. It abstracts network resources, allowing them to be managed independently of the underlying physical hardware.

In a Cisco environment, network virtualization can be implemented through various technologies:

- VLANs for Layer 2 segmentation

- VRF (Virtual Routing and Forwarding) for Layer 3 segmentation

- VXLAN (Virtual Extensible LAN) for extending Layer 2 domains across Layer 3 boundaries

- Cisco ACI (Application Centric Infrastructure) for policy-based automation and management

- Cisco NSX for comprehensive network virtualization in data centers

- Overlay networks using technologies like MPLS or GRE tunnels

A strong candidate should be able to explain these concepts clearly and discuss the benefits of network virtualization, such as improved resource utilization, enhanced security through isolation, and increased flexibility in network design. Look for understanding of how these technologies can be applied in real-world scenarios and any experience the candidate has in implementing them.

7. How would you design and implement a large-scale IPv6 deployment in an enterprise that's currently using IPv4?

A well-thought-out answer should include the following steps:

- Assess current network infrastructure and identify IPv6-compatible devices

- Plan the IPv6 addressing scheme and obtain address allocations

- Implement dual-stack configurations on core devices

- Configure IPv6 routing protocols (e.g., OSPFv3, BGP for IPv6)

- Set up IPv6 security measures (e.g., IPv6 ACLs, RA Guard)

- Implement transition mechanisms like 6to4 or ISATAP if needed

- Update DNS infrastructure to support IPv6 (AAAA records)

- Test IPv6 connectivity and performance

- Gradually enable IPv6 on end-user devices and servers

- Monitor and troubleshoot the IPv6 deployment

Look for candidates who understand the challenges of IPv6 deployment and can discuss strategies for coexistence with IPv4. They should be able to explain the benefits of IPv6 and potential pitfalls to avoid during the transition. Ask about any real-world experience they have with IPv6 deployments or pilot projects.

8. Describe how you would implement and manage a large-scale SD-WAN deployment across multiple sites.

A comprehensive answer should cover the following aspects of SD-WAN implementation and management:

- Assess current WAN infrastructure and requirements

- Choose an appropriate SD-WAN solution (e.g., Cisco SD-WAN, VMware SD-WAN)

- Design the SD-WAN architecture, including hub and spoke sites

- Plan for redundancy and failover mechanisms

- Implement centralized management and orchestration

- Configure traffic steering policies based on application requirements

- Set up security features like encryption and segmentation

- Integrate with existing network and security infrastructure

- Implement QoS policies for critical applications

- Set up monitoring and analytics for performance optimization

- Plan for scalability and future growth

Look for candidates who can explain the benefits of SD-WAN, such as improved application performance, reduced costs, and increased agility. They should demonstrate understanding of how SD-WAN differs from traditional WAN architectures and be able to discuss potential challenges in implementation. Ask about their experience with specific SD-WAN technologies and how they've addressed issues like change management and user adoption in previous deployments.

12 situational Microsoft Dynamics 365 SCM Manufacturing interview questions with answers for hiring top specialists

To determine whether your applicants have the right technical understanding of Cisco Networking, ask them some of these interview questions about protocols and configurations. This list will help you evaluate their hands-on experience and problem-solving skills when working with network protocols and configuring Cisco devices. By focusing on these questions, you can ensure that your potential hires possess the necessary expertise for roles such as network managers and network engineers.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

To assess a candidate's ability to handle real-world networking challenges, use these troubleshooting and diagnostic questions. They will help you evaluate the practical skills and problem-solving abilities essential for a Cisco networking professional.

To effectively gauge a candidate's problem-solving skills and decision-making abilities in the realm of Cisco networking, utilize this list of situational interview questions. These questions are designed to prompt candidates to think critically about real-world scenarios they might encounter in roles such as a network engineer.

Which Microsoft Dynamics 365 SCM Manufacturing skills should you evaluate during the interview phase?

While a single interview does not provide enough bandwidth to fully assess a candidate, certain core skills relevant to Microsoft Dynamics 365 SCM Manufacturing must be evaluated to gauge their proficiency. These skills are strategic to not only understanding their technical abilities but also their potential to drive value in real-world SCM scenarios.

Supply Chain Management

Understanding Supply Chain Management (SCM) is fundamental for candidates handling Microsoft Dynamics 365 SCM Manufacturing, as it directly relates to their ability to manage and optimize supply chains. This skill ensures they can effectively oversee production flow, from raw materials to production to the delivery of the final product.

To initially assess knowledge in SCM, consider incorporating an assessment test with relevant MCQs that can help filter candidates proficient in this area. While our library currently does not include a dedicated SCM test, this approach is a practical initial filtering step.

During the interview, it's also useful to ask specific questions that can help illuminate the candidate's depth of understanding in SCM.

Can you describe how Microsoft Dynamics 365 SCM Manufacturing can be utilized to improve supply chain transparency?

Listen for answers that demonstrate a clear understanding of Dynamics 365 features like real-time tracking and analytics, and how these can be leveraged to enhance visibility and coordination across the supply chain.

Process Optimization

Process optimization skills are key for roles involving Microsoft Dynamics 365 SCM Manufacturing, as they allow the candidate to streamline production processes, thereby enhancing efficiency and reducing costs within the manufacturing workflow.

To assess this skill, multiple-choice questions can be an effective preliminary test. While specific tests for this skill are not present in our library, creating scenario-based questions related to manufacturing process optimization can be beneficial.

Further exploration of this skill can be achieved by posing targeted interview questions.

How would you use Microsoft Dynamics 365 SCM Manufacturing to identify and address bottlenecks in production?

The candidate's answer should ideally reflect an understanding of using Dynamics 365's analytical tools to diagnose process inefficiencies and propose actionable solutions.

Data Analysis and Reporting

Proficiency in data analysis and reporting is crucial for candidates managing Microsoft Dynamics 365 SCM Manufacturing because it involves analyzing large volumes of data to make informed decisions that influence the manufacturing and supply chain strategies.

You could utilize assessment tests with MCQs focused on data analysis to gauge preliminary understanding. For specialized Dynamics 365 data analysis skills, consider using our Dynamics 365 SCM test.

Further testing in an interview can be conducted through specific questions tailored to Dynamics 365 SCM.

What methods would you employ in Dynamics 365 SCM Manufacturing to analyze production data and prepare reports for stakeholders?

Effective responses should include mention of specific Dynamics 365 tools or features such as Power BI integration for advanced data visualization and report customization.

Microsoft Dynamics 365 Supply Chain Management Functional Consultant Test

Download Microsoft Dynamics 365 SCM Manufacturing interview questions template in multiple formats

Microsoft Dynamics 365 SCM Manufacturing Interview Questions FAQs

Microsoft Dynamics 365 SCM Manufacturing is a module designed to manage production, supply chain operations, and manufacturing processes within an organization.

Process-related questions help you evaluate how well candidates understand and can navigate the workflows and operations within Microsoft Dynamics 365 SCM Manufacturing.

Situational interview questions present candidates with hypothetical scenarios to assess their problem-solving abilities and decision-making skills.

These questions help determine the candidate's technical proficiency and ability to configure and tailor the system to meet business needs.

A junior specialist should have basic knowledge of Microsoft Dynamics 365 SCM Manufacturing, an understanding of manufacturing processes, and good problem-solving skills.

Review the questions and answers provided to assess the candidate's knowledge, practical skills, and problem-solving abilities tailored to Microsoft Dynamics 365 SCM Manufacturing.

40 min skill tests.

No trick questions.

Accurate shortlisting.

We make it easy for you to find the best candidates in your pipeline with a 40 min skills test.

Try for freeRelated posts

Free resources